Providing mixing solutions to help you process fluids faster, more profitably, and more reliably. By working with UET Mixers, mixing will be one less thing you have to worry about.

For the past 30 plus years we have been lucky enough to work with many amazing companies. If you are one of them, thank you for the opportunity to be part of your success. If you are new to UET Mixers, please consider this a warm welcome from all of us.

See how to build professional charts and graphs for your presentations, marketing brochures, infographics, and much more using Adobe Illustrator. Try for free today! The Computer-Aided Design ('CAD') files and all associated content posted to this website are created, uploaded, managed and owned by third party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray. Inputs for agitator design: Design pressure: 6 kg/cm 2 / F.V. Design temperature: 75°C to 200°C Vessel working capacity: 6.3 KL Vessel inside diameter (D): 1950 mm Vessel T.L.-T.L. Length: 2200 mm Maximum mixing speed (N): 150 RPM Density of working fluid: 1000 kg/m 3 Viscosity of working fluid: 10000 CP MOC: Hastelloy C-22. Cerebromix is used for the calculation of agitated non-pressurised process tanks. It includes all of the features of Cerebrotank, plus the complete design of tank agitators including impeller design. CHAPTER 1: YOUR DATA IS VITAL! Defining your products and processes is essential to be able to calculate and design the agitator that best suits your needs. WHAT ARE YOUR PRODUCTS LIKE?

Static Mixers

Superior Technology,

Superior Performance

Design Philosophy

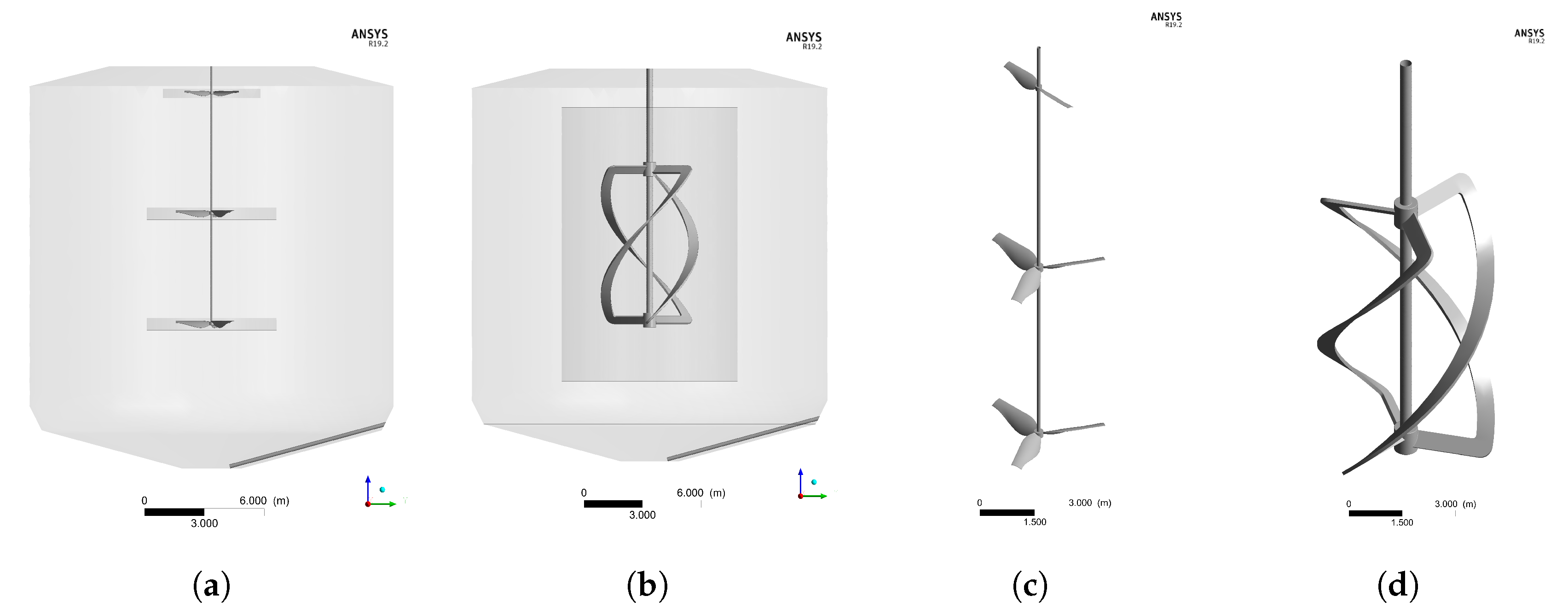

UET Mixers uses proprietary mixer design software, computational fluid dynamics (CFD), and good old-fashioned experience to delivery custom mixer designs that meet the requirements of your specific application. We will work with you to completely analyze your process and design the perfect mixing solution.

A division of Downeast Machine & Engineering, Inc.

26 Maple St.

Mechanic Falls, ME 04256

Phone:207-345-3330

Fax:207-345-3301

E-Mail: sales@uetmixers.com

Introduction to agitator design:

Agitators are machines used in industries for mixing fluids. In industries mixing of fluids is necessary for many chemical processes. It may include mixing of liquid with liquid, gas with a liquid, or solids with liquid. Mixing is accomplished by the rotating action of an impeller in the continuous fluid. Type of fluid and its physical state, the degree of agitation and geometry of vessel are key factors in the design and selection of agitator components.Here we will discuss the design of agitator vessel based on practical data inputs as given below:Inputs for agitator design:

Design pressure: 6 kg/cm2 / F.V.Design temperature: 75°C to 200°CVessel working capacity: 6.3 KLVessel inside diameter (D): 1950 mmVessel T.L.-T.L. length: 2200 mmMaximum mixing speed (N): 150 RPMDensity of working fluid: 1000 kg/m3Viscosity of working fluid: 10000 CPMOC: Hastelloy C-22Solution:

Step-1: Power calculations and selection of motor

For required power calculations, selection of the type of impeller is very important to achieve required agitation power. Selection of impeller is done based on application and type of flow. Flat paddle, turbine, anchor type, pitched blade impellers are used most commonly. For given type of agitation flat paddle impeller is used as given below:After selection of impeller dimensionless number Reynold’s number is calculated as given belowRe = ρ*N*d

5/ µFrom generic agitator curve, as shown in Fig.1, impeller power number is calculated based on calculated Reynold’s number.Fig. 1 – Power number against Reynolds number of some turbine impellers [Ref. Bates, Fondy, and Corpstein, Ind. Eng. Chem. Process. Des. Dev. 2(4) 311 (1963)]Based on impellers selected the layout of the shaft is done as shown in Fig.2.Fig.2 Agitator assembly layout

5/ µFrom generic agitator curve, as shown in Fig.1, impeller power number is calculated based on calculated Reynold’s number.Fig. 1 – Power number against Reynolds number of some turbine impellers [Ref. Bates, Fondy, and Corpstein, Ind. Eng. Chem. Process. Des. Dev. 2(4) 311 (1963)]Based on impellers selected the layout of the shaft is done as shown in Fig.2.Fig.2 Agitator assembly layoutStep 2: Design of shaft

Design of solid shaft subjected to shear stressFor selected motor power rated torque and maximum torque is calculated as given below:Rated torque: Tr = P*4500 / 2*π*NMaximum torque: Tm= (1.5 to 2.5) TrTherefore, solid shaft diameter is calculated byTm = π* ζ*ds3/16Step:3 Design of solid shaft subjected to pure bending

Maximum bending force is assumed to be acting at the point of jamming i.e. 0.75 of maximum agitator radius from the axis.Maximum bending force Fm = Tm/0.75*rMaximum bending moment Mm= π*бb*ds3/32Step:4 Design of solid shaft subjected to bending and twisting

According to maximum shear stress theory for ductile material, equivalent twisting moment is calculated asTe = √(Mm2+Tm2) = π* ζ*ds 3/16According to maximum normal stress theory for brittle material, equivalent bending moment is calculated asTe = ½ ( Mm+√(Mm2+Tm2) ) = π*бb*ds3/32Larger of all calculated diameters is considered as the minimum required diameter of the shaft. Therefore, selecting shaft diameter of 100mm, the shaft is checked for critical speed.

3/16According to maximum normal stress theory for brittle material, equivalent bending moment is calculated asTe = ½ ( Mm+√(Mm2+Tm2) ) = π*бb*ds3/32Larger of all calculated diameters is considered as the minimum required diameter of the shaft. Therefore, selecting shaft diameter of 100mm, the shaft is checked for critical speed.Step:5 Design of solid shaft based on critical speed